Common Mistakes to Avoid in T-Shirt Manufacturing

T-shirt manufacturing is not just about stitching fabric; it involves a precise blend of design, material selection, and production processes. Avoiding the list of the below common mistakes can significantly improve high-quality product output and long-term brand success.

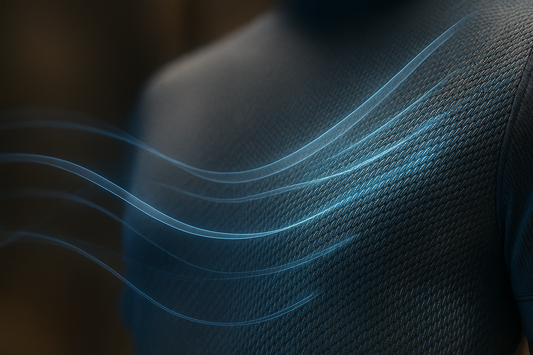

Choosing the Wrong Fabric Quality

The selection of fabric is the cornerstone of any T-shirt manufacturing process. Choosing the wrong type—be it overly synthetic, rough in texture, or low in durability—can impact both comfort and longevity. T-shirts made from low-grade fabric may feel uncomfortable, shrink excessively, or lose shape quickly, leading to customer dissatisfaction and high return rates. Whether you're a T-shirt manufacturer in India catering to the local or international market, it's critical to use materials that align with your brand’s value proposition. Premium options like Supima cotton, organic cotton, and moisture-wicking blends enhance product value and user experience. Proper fabric selection also ensures a smoother printing, stitching, and dyeing process down the line.

Ignoring Fabric Shrinkage and Stretch Tests

Many T-shirt manufacturers overlook fabric testing before bulk production, which can lead to serious post-sale issues. Fabric shrinkage and stretch tolerance should be thoroughly tested to avoid unexpected size changes after washing. Shrinkage greater than 5% is often considered unacceptable in retail garments. Similarly, poor elasticity can result in misshapen t-shirts that lose their form quickly. Testing helps identify how a fabric behaves under stress and washing conditions. By conducting proper shrinkage and stretch tests, manufacturers ensure better fit, longer garment life, and higher customer satisfaction. This practice also minimizes returns and boosts brand reliability.

Overlooking Proper Pattern Making and Grading

Pattern making and grading are technical yet critical steps in T-shirt manufacturing. Poor pattern construction can result in ill-fitting garments, inconsistent silhouettes, and size discrepancies across batches. Grading ensures that the same design scales proportionally across different sizes. Without proper grading, larger or smaller sizes may appear distorted or uncomfortable to wear. This is especially important for T-shirt manufacturers in India, where customer sizing can vary widely by region. Investing in experienced pattern makers and using advanced CAD tools for precision grading can help maintain consistency and quality across all production runs.

Poor Cutting Techniques and Inaccurate Marking

Cutting is more than slicing fabric—it’s about precision and efficiency. Errors in cutting or marking can lead to fabric wastage, poor fit, and uneven stitching lines. In mass production, even a 1% error in cutting can translate into significant losses. Inaccurate marking can also disrupt alignment during stitching or printing. T-shirt manufacturers in Tirupur using manual methods should ensure workers are trained and supervised. Automated cutting machines, when feasible, provide better consistency and speed. Accurate templates, proper layer alignment, and routine quality checks during the cutting stage contribute to smoother production and higher output quality.

Inconsistent Stitching and Seam Quality

Seam durability is a mark of well-made apparel. In T-shirt manufacturing, inconsistent stitching loose threads, skipped stitches, or unbalanced tension—can lead to garment failure. Poor seam quality affects both appearance and wearability. It can also cause issues like puckering or fraying. A reliable T-shirt manufacturer in India pays close attention to seam construction using the appropriate stitch type (e.g., overlock, flatlock, or cover stitch) based on the garment design. Investing in skilled labor and high-quality machinery ensures consistent stitch quality across all garments. Seam strength tests should be part of the final quality control process.

Neglecting Color Fastness and Dye Quality

Color bleeding, fading, or patchy dyeing can damage the brand image of any T-shirt manufacturer. Color fastness testing ensures that dyes are firmly fixed and don’t bleed during washing or wear. Low-quality dyes can cause skin irritation and create environmental hazards during manufacturing. Using certified dyes and performing wash, rub, and light tests helps ensure color longevity. Partnering with dye houses that follow eco-friendly and sustainable practices is also crucial. This not only improves the product’s visual appeal but also positions your brand as responsible and high-quality in a competitive market.

Improper Printing and Dye Quality

Printing is a value-adding process that must not be compromised. Issues such as blurred prints, off-placement, cracking, or poor color matching often stem from improper techniques or low-quality inks. This can lead to customer dissatisfaction, especially in fashion or custom-print t-shirts. Whether it’s screen printing, DTG, or sublimation, every T-shirt manufacturer in India should ensure alignment between fabric type and print method. Using the wrong ink on the wrong fabric can lead to rapid deterioration. Always conduct test prints and quality assurance checks before mass printing to avoid costly mistakes and product rejections.

Skipping Quality Control Checks

Quality control (QC) is often viewed as a final step, but it must be integrated throughout the T-shirt manufacturing process. Skipping or minimizing QC can result in entire batches being rejected due to defects like misaligned seams, dye stains, or faulty labels. For a T-shirt manufacturer in Tirupur, implementing multi-stage QC from raw material inspection to final packing can drastically improve consistency. A robust QC protocol ensures that only products meeting predefined standards reach the customer. This minimizes returns, enhances customer satisfaction, and strengthens brand credibility.

Inadequate Size and Fit Standardization

Consistency in size and fit builds customer trust. T-shirts that vary in measurement across batches can lead to dissatisfaction and returns. Many T-shirt manufacturers fail to define or follow a standard sizing chart, leading to garments that don’t fit as expected. Collaborating with fashion designers or consultants to establish region-specific sizing can solve this issue. Periodic sample testing and size validation across production cycles further ensure reliability. Clear size labeling and alignment with online size charts also help customers make informed purchases, reducing fit-related complaints.

Underestimating Packaging and Labeling Standards

Packaging and labeling might seem like finishing touches, but they carry significant functional and branding value. Damaged or poorly packed t-shirts create a negative unboxing experience. Incomplete or incorrect labeling can also cause compliance issues in retail. Every T-shirt manufacturer in India, especially exporters, must adhere to local and international labeling norms regarding fabric composition, size, care instructions, and country of origin. High-quality packaging also protects the garment in transit and boosts shelf appeal. Eco-friendly and branded packaging solutions offer a competitive advantage while aligning with sustainability goals.

Ignoring Eco-Friendly Practices

Sustainability is no longer optional in the T-shirt manufacturing industry. From fabric sourcing to dyeing and packaging, eco-conscious practices appeal to modern consumers. Many T-shirt manufacturers are adopting organic cotton, low-impact dyes, and water-efficient processes to meet global standards. Ignoring these trends can alienate environmentally aware buyers and limit access to export markets. Implementing certifications like GOTS or OEKO-TEX® can enhance brand value and attract more retail partnerships. Eco-friendly production is not only ethically sound but also financially beneficial in the long term through brand loyalty and regulatory compliance.

Lack of Clear Communication With Suppliers and Manufacturers

Miscommunication can disrupt timelines, budgets, and product quality. In T-shirt manufacturing, clarity between buyers, suppliers, and internal teams is crucial. Poor documentation, vague briefs, or last-minute changes often lead to delays and cost overruns. Every T-shirt manufacturer in India should establish SOPs (standard operating procedures) for communication, including production updates, change management, and approval workflows. Using digital tools like production management software or shared platforms helps maintain transparency and accountability across all stakeholders involved.

Ignoring Consumer Feedback and Market Trends

A successful T-shirt manufacturers must stay attuned to evolving market demands. Ignoring feedback whether through customer reviews, sales data, or retail partners can result in stagnation. Trends in fabric, fit, color, and design evolve rapidly. Manufacturers that actively monitor fashion shifts and consumer preferences can adjust their production strategies accordingly. Market research, competitor analysis, and pilot launches can help validate product ideas before large-scale production. Listening to end-users helps refine both the product and the brand's value proposition.

Rushing the Sampling and Prototyping Phase

Sampling is the foundation of bulk production. Rushing through it leads to unnoticed flaws, which can amplify during full-scale manufacturing. Prototypes must be tested for fit, finish, stitching, and print accuracy. Every T-shirt manufacturer in India should involve stakeholders, designers, quality inspectors, and buyers in sample evaluations. Feedback from the sampling phase should inform necessary adjustments. A detailed and careful sampling process reduces risks, improves final product quality, and ensures that what’s envisioned is what’s delivered.

Not Accounting for Production Scalability

Many T-shirt manufacturers start with small batches without planning for scale. As demand grows, capacity, supply chain, and manpower must scale proportionally. Without proper planning, this can lead to production delays, compromised quality, and lost opportunities. Manufacturers should assess machinery, vendor capacity, storage, and staffing well in advance. Scalable systems allow for seamless expansion without disrupting workflow. Whether producing for local brands or international retailers, having a flexible yet robust production infrastructure is key to sustained growth in T-shirt manufacturing.