The Environmental Impact of T-Shirt Manufacturing

That comfortable cotton T-shirt in your wardrobe has a story—one that extends far beyond the retail store. Behind every garment lies a complex manufacturing process that significantly impacts our environment. As consumers become increasingly conscious of sustainability, understanding the environmental footprint of T-shirt production has never been more crucial.

The fashion industry ranks as the second-most polluting industry globally, with T-shirt manufacturing playing a substantial role in this environmental challenge. From cotton cultivation to final packaging, each step in the production chain leaves an ecological footprint that affects water resources, air quality, and climate change.

The Water Crisis in T-shirt Production

Water consumption represents one of the most significant environmental impacts of T-shirt manufacturing. The numbers are staggering and often surprise consumers.

Cotton's Thirsty Reality

Conventional Cotton Production requires approximately 2,700 liters of water to produce a single T-shirt—equivalent to what an average person drinks over 2.5 years. This massive water consumption occurs primarily during the cotton growing phase, where irrigation demands are exceptionally high.

Regional Water Stress becomes particularly concerning in major cotton-producing regions like India, Pakistan, and Uzbekistan, where water scarcity already poses significant challenges to local communities.

Manufacturing Process Water Use

Beyond raw material production, T-shirt manufacturing involves multiple water-intensive processes:

- Dyeing and Printing: Requires 100-150 liters of water per kilogram of fabric

- Washing and Finishing: Additional 50-100 liters per garment

- Quality Control: Final washing and treatment processes

The textile industry accounts for 20% of global water pollution, making it a critical environmental concern requiring immediate attention.

Chemical Pollution and Toxic Impact

T-shirt manufacturing relies heavily on chemicals throughout the production process, creating serious environmental and health concerns.

Pesticide Use in Cotton Farming

Conventional Cotton cultivation uses approximately 16% of the world's pesticides despite occupying only 2.5% of agricultural land. These chemicals:

- Contaminate soil and groundwater

- Harm beneficial insects and biodiversity

- Pose health risks to agricultural workers

- Persist in the environment for years

Dyeing and Chemical Processing

Textile Dyeing introduces numerous toxic substances into the environment:

- Azo Dyes: Can release carcinogenic compounds

- Heavy Metals: Lead, mercury, and chromium contamination

- Formaldehyde: Used in wrinkle-resistant treatments

- Bleaching Agents: Chlorine-based chemicals affecting water quality

Many of these chemicals end up in water systems, affecting aquatic life and contaminating drinking water sources in manufacturing regions.

Carbon Footprint and Climate Impact

The fashion industry contributes approximately 10% of global carbon emissions, with T-shirt production representing a significant portion of this impact.

Manufacturing Emissions

Energy Consumption in T-shirt production occurs across multiple stages:

- Cotton Processing: Ginning, spinning, and weaving require substantial energy

- Dyeing and Finishing: High-temperature processes consume significant electricity

- Transportation: Global supply chains involve extensive shipping and logistics

Fast Fashion Acceleration

Rapid Production Cycles have intensified environmental impact:

- Increased manufacturing frequency

- Higher waste generation from unsold inventory

- Shortened garment lifespans leading to more frequent replacement

- Greater pressure on natural resources

Waste Generation Throughout the Supply Chain

T-shirt manufacturing generates waste at every production stage, creating disposal challenges worldwide.

Pre-Consumer Waste

Manufacturing Waste includes:

- Fabric Scraps: 15-20% of fabric becomes waste during cutting

- Defective Products: Quality control rejects

- Overproduction: Excess inventory that never reaches consumers

Post-Consumer Disposal

End-of-Life Impact presents growing challenges:

- Only 15% of clothing gets recycled globally

- Synthetic blends take 20-200 years to decompose

- Landfill accumulation continues to grow exponentially

- Incineration releases toxic fumes and greenhouse gases

Sustainable Alternatives and Solutions

Despite these challenges, innovative solutions are emerging to reduce T-shirt manufacturing's environmental impact.

Sustainable Materials

Organic Cotton reduces environmental impact by:

- Eliminating synthetic pesticides and fertilizers

- Using 91% less water than conventional cotton

- Improving soil health and biodiversity

- Supporting farmer health and welfare

Recycled Materials offer promising alternatives:

- Recycled Cotton: Reduces demand for virgin materials

- Recycled Polyester: Diverts plastic bottles from landfills

- Hemp and Bamboo: Fast-growing, low-impact alternatives

Innovative Manufacturing Practices

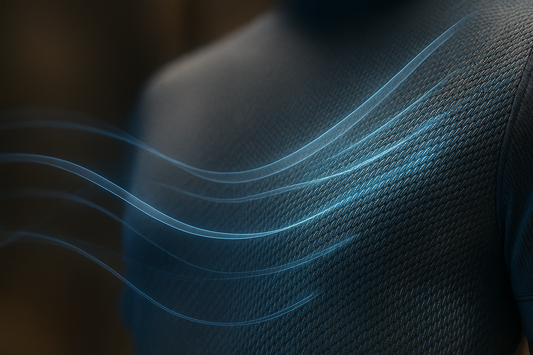

Waterless Dyeing Technologies are revolutionizing the industry:

- Air Dyeing: Reduces water usage by 95%

- Digital Printing: Eliminates chemical waste

- Natural Dyes: Plant-based alternatives to synthetic chemicals

Circular Manufacturing approaches include:

- Zero-waste Design: Minimizing fabric waste during production

- Closed-loop Systems: Recycling production waste back into manufacturing

- Local Production: Reducing transportation emissions

Consumer Impact and Responsibility

Individual choices significantly influence the environmental impact of T-shirt consumption and disposal.

Conscious Purchasing Decisions

Quality over Quantity represents the most impactful consumer choice:

- Invest in durable, well-made T-shirts

- Choose sustainable materials and ethical brands

- Consider cost-per-wear rather than initial price

- Support transparent supply chain practices

Extending Garment Lifespan

Proper Care dramatically reduces environmental impact:

- Wash in cold water to save energy

- Air dry instead of using electric dryers

- Follow care instructions to prevent premature wear

- Repair minor damage instead of discarding

End-of-Life Responsibility

Sustainable Disposal options include:

- Donate wearable garments to extend their life

- Recycle through textile recycling programs

- Repurpose old T-shirts for cleaning or crafts

- Choose brands with take-back programs

Industry Transformation and Future Outlook

The fashion industry is gradually embracing sustainability, driven by consumer demand and regulatory pressure.

Corporate Responsibility Initiatives

Major brands are implementing:

- Sustainable sourcing commitments

- Water reduction targets

- Chemical elimination programs

- Circular design principles

Technology and Innovation

Emerging technologies promise to revolutionize T-shirt manufacturing:

- Lab-grown Cotton: Eliminates agricultural water usage

- Enzymatic Recycling: Breaks down blended fabrics for reuse

- Blockchain Traceability: Ensures supply chain transparency

- AI Optimization: Reduces waste through predictive manufacturing

Making Informed Choices

Understanding the environmental impact of T-shirt manufacturing empowers consumers to make responsible decisions that support both personal values and planetary health.

Every purchase represents a vote for the kind of fashion industry we want to support. By choosing sustainable options, extending garment lifespans, and disposing of clothing responsibly, consumers can significantly reduce their fashion footprint.

The path toward sustainable T-shirt manufacturing requires collaboration between consumers, brands, and policymakers. While challenges are significant, innovative solutions and changing consumer consciousness offer hope for a more sustainable fashion future.

Creating Sustainable Fashion Solutions

At Varthagam International, we're committed to helping apparel brands transition toward more sustainable manufacturing practices. From sourcing eco-friendly materials to implementing responsible production processes, we support businesses in reducing their environmental impact while maintaining quality and profitability.

Visit Varthagam international.in or Book a Call with us or Chat with us on Whatsapp to explore sustainable manufacturing solutions for your apparel brand.