Glossary of Terms Used in T-Shirt Manufacturing

The T-shirt manufacturing industry has its own unique language filled with technical terms, processes, and specifications that can be overwhelming for newcomers and even confusing for experienced professionals. Whether you're starting a clothing brand, working with suppliers, or simply want to understand the manufacturing process better, this comprehensive glossary will help you navigate the complex world of T-shirt production with confidence.

From fabric terminology to printing techniques, quality control measures to sizing standards, we've compiled the most essential terms you'll encounter in T-shirt manufacturing. Each definition is clear, concise, and designed to give you practical understanding that you can apply immediately in your business conversations and decisions.

Fabric and Material Terms

Bamboo Fiber - Eco-friendly fabric made from bamboo pulp, naturally antimicrobial and moisture-wicking.

Blend - Fabric made from two or more different fiber types combined for enhanced properties.

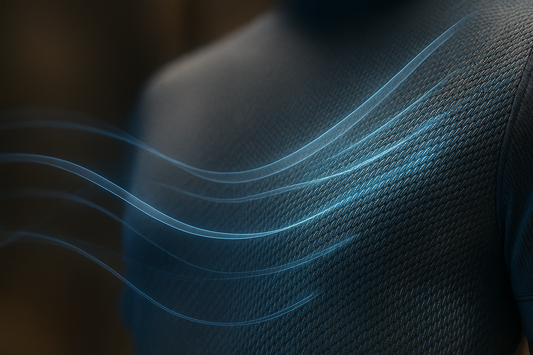

Breathability - A fabric's ability to allow air circulation and moisture vapor transmission.

Brushed Cotton - Cotton fabric with a soft, fuzzy surface created by brushing the fabric.

Combed Cotton - Cotton that has been combed to remove short fibers, resulting in smoother, stronger yarn.

Cotton - Natural fiber from cotton plants, most common material for T-shirts.

Denier - Unit measuring fiber thickness; lower denier means finer, softer fabric.

Drape - How fabric hangs and flows when worn or displayed.

DTY (Draw Textured Yarn) - Synthetic yarn process that creates stretch and texture.

Elastane - Synthetic fiber that provides stretch and recovery (also known as spandex or lycra).

French Terry - Knit fabric with loops on one side, commonly used for sweatshirts.

GSM (Grams per Square Meter) - Standard measurement of fabric weight and thickness.

Hand Feel - The tactile quality of fabric when touched or handled.

Hemp - Durable, natural fiber known for strength and environmental sustainability.

Jersey Knit - Single-knit fabric structure, most common for T-shirts.

Linen - Natural fiber from flax plants, known for breathability and casual drape.

Mercerized Cotton - Cotton treated with caustic soda for increased luster and strength.

Modal - Semi-synthetic fiber made from beech trees, softer than regular cotton.

Organic Cotton - Cotton grown without synthetic pesticides or fertilizers.

Pima Cotton - High-quality cotton variety with extra-long staple fibers.

Polyester - Synthetic fiber known for durability, wrinkle resistance, and quick drying.

Pre-shrunk - Fabric treated to minimize shrinkage after washing.

Rayon - Semi-synthetic fiber made from wood pulp, silky feel and drape.

Ring Spun Cotton - Cotton yarn spun using ring spinning method for softer texture.

Slub - Intentional thick and thin variations in yarn creating textured appearance.

Spandex - Synthetic elastic fiber providing stretch (same as elastane).

Supima Cotton - Premium American-grown Pima cotton with superior quality standards.

Tencel - Brand name for lyocell fiber, eco-friendly and moisture-wicking.

Thread Count - Number of threads per square inch, indicating fabric density.

Tri-blend - Fabric combining three fibers, typically cotton, polyester, and rayon.

Viscose - Type of rayon fiber with silk-like properties.

Wicking - Fabric's ability to pull moisture away from the body.

Manufacturing and Production Terms

Batch - Group of products manufactured together under same conditions.

Bias - Diagonal direction of fabric, provides stretch in woven materials.

Blank - Plain, undecorated garment ready for printing or embroidery.

Bleed - When dye or ink spreads beyond intended boundaries.

Colorfast - Fabric's ability to retain color without fading or running.

Cut and Sew - Manufacturing method where fabric is cut then sewn into garments.

Dye Lot - Batch of fabric dyed at same time; may vary slightly between lots.

Fabric Yield - Amount of finished fabric produced from raw materials.

Fully Fashioned - Garment knitted to shape rather than cut from fabric.

Grading - Process of scaling pattern pieces to different sizes.

Greige Goods - Unfinished fabric before dyeing, printing, or other treatments.

Lead Time - Time required from order placement to delivery.

Make Through - Complete production run of a style in all sizes and colors.

Marker - Layout pattern showing how to cut fabric pieces efficiently.

MOQ (Minimum Order Quantity) - Smallest order quantity a manufacturer will accept.

Pattern Making - Creating templates for cutting fabric pieces.

Pre-production Sample - Sample garment made before full production begins.

Production Sample - Sample from actual production run for approval.

Prototype - First sample of a new design for testing and approval.

Quality Control (QC) - Process of inspecting products for defects and standards compliance.

Sampling - Creating test garments before mass production.

Seamless - Garment construction without side seams, often using circular knitting.

Selvage - Finished edge of woven fabric that prevents unraveling.

Spec Sheet - Detailed document outlining garment specifications and requirements.

Strike Off - Sample showing how colors will look on specific fabric.

Tolerance - Acceptable range of variation in measurements or specifications.

Wash Care - Instructions for proper garment cleaning and maintenance.

Printing and Decoration Terms

All-Over Print - Design that covers the entire garment surface.

Base Layer - First layer of ink in multi-color screen printing.

Bleeding - Ink spreading beyond design boundaries, creating blurry edges.

Burn Test - Method to identify fiber content by observing how fabric burns.

CMYK - Four-color printing process using Cyan, Magenta, Yellow, and Black.

Curing - Heat treatment process that sets ink permanently into fabric.

Direct-to-Garment (DTG) - Digital printing method that prints directly onto fabric.

Discharge Printing - Technique that removes dye from fabric and replaces with new color.

Dye Sublimation - Process using heat to transfer dye into synthetic fabrics.

Embroidery - Decorative stitching using thread to create designs on fabric.

Foil Transfer - Application of metallic foil to fabric using heat and pressure.

Four-Color Process - Printing technique using CMYK colors to create full-color images.

Halftone - Printing technique using dots of varying sizes to create color gradations.

Heat Press - Machine using heat and pressure to apply transfers to garments.

Heat Transfer Vinyl (HTV) - Vinyl material applied to fabric using heat and pressure.

Ink Opacity - How well ink covers the fabric underneath.

Knockout - Removing underlying colors where top colors will be printed.

Overprint - Printing one color over another, creating color mixing.

Pantone - Standardized color matching system used in printing industry.

Peel Test - Quality test checking how well ink or transfer adheres to fabric.

Plastisol - Type of screen printing ink that sits on fabric surface.

Registration - Proper alignment of multiple colors in printing process.

Screen Printing - Method using mesh screens to transfer ink onto fabric.

Separation - Breaking down multi-color designs into individual color layers.

Spot Color - Single, solid color used in printing (opposite of process colors).

Squeeze - Amount of pressure applied during screen printing.

Strike Through - When ink penetrates too deeply, showing through fabric back.

Trapping - Slight overlap between colors to prevent white gaps.

Underbase - White ink layer printed first to make colors more vibrant on dark fabrics.

Vector Art - Scalable artwork created using mathematical formulas rather than pixels.

Water-based Ink - Eco-friendly ink that penetrates fabric fibers rather than sitting on top.

Sizing and Fit Terms

Armhole - Opening where sleeve attaches to body of garment.

Chest Width - Measurement across garment at chest level.

Drop Shoulder - Shoulder seam positioned below natural shoulder line.

Ease - Extra room built into garment for comfortable movement.

Fitted - Garment cut close to body shape with minimal ease.

Grading - Process of creating size range from base pattern.

Length - Measurement from shoulder to hem of garment.

Neckline - Opening around neck area of garment.

Oversized - Garment intentionally cut larger than standard measurements.

Regular Fit - Standard fit with moderate ease for comfort.

Relaxed Fit - Loose-fitting garment with extra ease throughout.

Shoulder-to-Shoulder - Measurement across garment from shoulder seam to shoulder seam.

Size Chart - Table showing measurements for each size in a size range.

Size Run - Complete range of sizes offered for a particular style.

Sleeve Length - Measurement from shoulder seam to end of sleeve.

Slim Fit - Garment cut closer to body than regular fit.

Tapered - Gradual narrowing from one area to another.

True to Size - Garment that fits according to standard size expectations.

Quality Control and Testing Terms

Abrasion Resistance - Fabric's ability to withstand wear from rubbing or friction.

AQL (Acceptable Quality Level) - Maximum number of defects considered acceptable.

Bursting Strength - Maximum pressure fabric can withstand before tearing.

Color Matching - Ensuring colors match approved standards or samples.

Defect - Flaw or imperfection that affects garment quality or appearance.

Dimensional Stability - Fabric's ability to maintain size after washing.

Durability - How well a garment withstands regular use and washing.

Fastness - Resistance of colors to fading, bleeding, or changing.

Fabric Inspection - Systematic examination of fabric for defects before cutting.

Final Inspection - Last quality check before garments are packed for shipping.

Hand Feel Test - Subjective evaluation of fabric softness and texture.

Laundry Test - Washing garments to check shrinkage, color retention, and durability.

Measurement Tolerance - Acceptable range of variation from specified measurements.

Pilling - Formation of small fiber balls on fabric surface from wear.

QA (Quality Assurance) - Overall process ensuring products meet quality standards.

Random Sampling - Selecting random pieces from production for quality testing.

Rejection Rate - Percentage of products that don't meet quality standards.

Seam Strength - How much force a sewn seam can withstand before breaking.

Shrinkage Test - Measuring how much fabric contracts after washing.

Tensile Strength - Maximum stress fabric can withstand while being stretched.

Business and Trade Terms

B2B (Business to Business) - Commercial transactions between businesses.

B2C (Business to Consumer) - Commercial transactions between business and end customers.

CMT (Cut, Make, Trim) - Manufacturing service where contractor cuts, sews, and finishes garments.

Cost Sheet - Detailed breakdown of all costs involved in garment production.

Customs Clearance - Process of getting imported goods approved by customs authorities.

Duty - Tax imposed on imported goods.

Ex-Factory Price - Price of goods at manufacturer's facility, excluding shipping.

FOB (Free on Board) - Shipping term indicating when ownership transfers from seller to buyer.

Import License - Government permit required to bring goods into a country.

Incoterms - International commercial terms defining buyer and seller responsibilities.

Invoice - Bill sent by seller to buyer for goods or services.

Letter of Credit (LC) - Financial document guaranteeing payment from buyer's bank.

OEM (Original Equipment Manufacturer) - Company that manufactures products for other brands.

ODM (Original Design Manufacturer) - Company that designs and manufactures products for other brands.

Packing List - Document listing contents of each shipping container or package.

Private Label - Products manufactured by one company but sold under another company's brand.

Proforma Invoice - Preliminary bill of sale sent before goods are delivered.

Quota - Limit on quantity of goods that can be imported during specific period.

Tariff - Tax on imported goods, usually calculated as percentage of value.

Trade Terms - Conditions governing international commercial transactions.

Sustainability and Certification Terms

Better Cotton Initiative (BCI) - Program promoting sustainable cotton farming practices.

Carbon Footprint - Total greenhouse gas emissions produced during manufacturing.

Certified Organic - Products meeting strict organic production standards.

Cradle to Cradle - Design philosophy considering product's entire lifecycle.

Eco-Friendly - Products or processes with minimal environmental impact.

Fair Trade - Certification ensuring fair wages and working conditions for workers.

GOTS (Global Organic Textile Standard) - Leading standard for organic fiber textiles.

Green Manufacturing - Production methods designed to minimize environmental impact.

Life Cycle Assessment (LCA) - Analysis of environmental impacts throughout product's life.

OEKO-TEX Standard 100 - Certification for textiles free from harmful substances.

Recycled Content - Percentage of product made from recycled materials.

Renewable Resources - Materials that can be replenished naturally over time.

Sustainable Fashion - Clothing designed and produced with environmental and social responsibility.

Traceability - Ability to track product's journey from raw materials to finished goods.

Water Footprint - Total amount of water used in product's production process.

Zero Waste - Manufacturing approach that eliminates waste sent to landfills.

Final Thoughts

Understanding T-shirt manufacturing terminology is essential for anyone involved in the apparel industry. This glossary provides the foundation you need to communicate effectively with suppliers, manufacturers, and industry professionals. Whether you're negotiating contracts, discussing quality standards, or planning production schedules, knowing these terms will help you make informed decisions and avoid costly misunderstandings.

The T-shirt manufacturing industry continues to evolve with new technologies, sustainable practices, and changing consumer demands. Stay updated with industry developments and don't hesitate to ask for clarification when encountering unfamiliar terms. Clear communication is key to successful manufacturing partnerships and quality product development.

Ready to Start Your T-Shirt Manufacturing Journey?

At Varthagam International, we help apparel brands navigate the complex world of T-shirt manufacturing with expert guidance and industry connections. From sourcing fabrics to quality control and production management, we ensure your manufacturing process runs smoothly.

Visit Varthagam international.in or Book a Call with us or Chat with us on Whatsapp to discuss your manufacturing needs and get started with confidence.